I decided it was time to use the Miller Spool Mate 100 spool gun that came with my Millermatic 211 Auto-Set MIG. The first project I tried it on it did well, I melted a few tips but it wasn’t so bad. The second one, when I finally got the settings hot enough POOFZAP! No more tip… After 30 minutes of taking the gun apart, clearing the bird's nests and some choice foul language… I was ready to go again.

POOFZAP! CRAP!

(half an hour of muttering and swearing at the thing, I mean clearing the bird's nest and rollers)

POOFZAP! WHAT THE… is wrong with this ARGH!!!

I need more tips.

The LWS (Local Welding Supply, conveniently at the end of the next street over) hands me some standard Miller MIG tips… nope, the spool gun uses little tiny ones. That no one carries.

{insert your favorite foul language, I’m sure I used it at this point}

I finally found them at Robert’s Oxygen after searching for 2 days. Man those little buggers are expensive… why the heck didn’t they use the same tip as every other Miller and Hobart MIG gun use (M-15 style)? Oh well…

POOFZAP!

POOFZAP!

POOFZAP! FLLAASSHHHHH! Even the gun liner melted into the tip!

WHAT IS THIS SOME CRUEL JOKE?!? Let’s consult the all knowing Googles and see what’s up…

I found that I wasn’t the only one (does that make it better or worse? I don’t know…), and that any heavier job tended to melt tips. Right, and you can’t really weld light aluminum with a MIG, so HOW DOES IT MAKE SENSE TO USE THE TINY LITTLE TIPS???

I posted to a couple of welding forums and learned that there was a guy named Bob that will convert your spool gun barrel to use the standard M-15 gun tips but no luck finding any more information about “Bob,” just that “you can’t do this with normal tools.”

Yea… fortunately, I’m not normal…

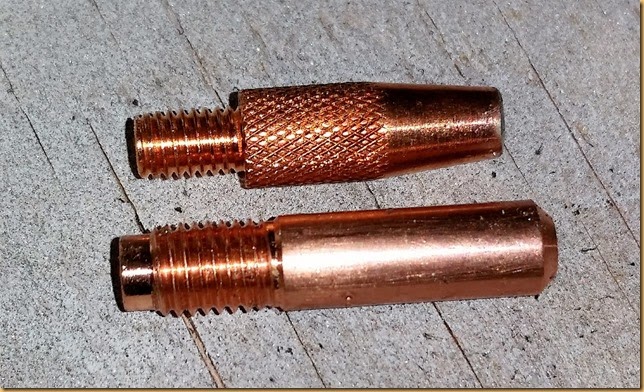

This:

turned into this:

So how do I put the bottom one where Miller thought (wrongly) the top one should go? Now I understood the “normal tools” comment, that barrel that the tip threads into is thin:

No problem (famous last words). Unthread the barrel (and figure out that every wrench you have is too big to get in there without totally disassembling it), push it out of the insulator and pop out the alignment pin (and drop it and spend the next 15 minutes looking for it).

The M-15 tips look to have a 1/4-28* thread on them… Ok… Throw it in the lathe chuck, grab a #3 (7/32”) drill bit and drill out the end of the barrel (fair warning, this ends up pretty thin), I decided that about 3/4” was deep enough to run the tap in far enough:

ACTUALLY, at first I decided that 1/2” was, then after bottoming the tap out before having enough threads to thread the tip in I had to carefully drill them deeper without messing up the threads… :-/

1/4-28 tap* using a tap guide in the tailstock chuck:

Ah, a thing of beauty:

Reverse steps for reassembly:

Yea, that gun nozzle still has some melted copper (probably a copper aluminum alloy  ) from melting tips earlier.

) from melting tips earlier.

How does it work? I haven’t melted a tip running 4043 since and can lay down some pretty stacks of dimes with it and now, again, I only have to keep one style of tip around.

HURRAY!!!

What the heck am I going to do with the pack of 10 of small tips that I have left???

I originally did this so I could run 5356 (it wouldn’t work at all with the original tips, I haven’t been able to find documentation to this effect but I looks like it takes quite a bit more heat to get a good bead with), but I haven’t had time to get back to that project yet. I’ll try to remember to update this when I do.

* interesting note, Lincoln/Tweco tips will thread into Miller guns, but not vice versa. They appear to be a slightly smaller, coarser thread (I’m pretty sure they’re metric but I haven’t taken the time to figure out exactly what), that threads and holds in the 1/4-28 female thread fine.6/12/2017- At this point I've done half a dozen of them, they've all gone fine and worked much better.

3 comments:

Bob was a mystery for me as well. Interesting project. The 5356 runs through the original tips much better. I believe it is because the wire is stiffer. I never had it birds nest but I can't say that about the 4043. It was a pain!

HI I am BOB aametalmaster to be exact. I designed how to do the Miller Spoolmate Tips to the standard Miller Mig Tips. Thanks for mentioning me....Bob aametalmaster@yahoo.com

Hi there to all, how is everything, I think every one is getting more from this web site, and your views are fastidious designed for new visitors.

Post a Comment