When last we left our intrepid hero…

I’m sure I was doing something.

(I need to get some better CAD software, but even with SketchUp you have to love how easy it is to manipulate your drawings. I remember playing with a _really early version of AutoCAD in the early 80’s in my dad’s engineering consulting office on weekends, the PC AT with a HDD and 3 color screen… was just incredible. I was 10 or 12 at the time)

OK, so with the adjustable feet made, casters bought… I could figure out the remaining dimensions and actually build the thing.

Guess what? I found the 2 bolts that I lost in the last installment. They were under the hood of a car that I haven’t driven for roughly 10 months… HOW DID THEY GET THERE??? Damned Dwarves…

Lets get started.

First thing I did is measured out the 3” box section pieces for the uprights/legs, threw them on my 4x6 bandsaw and cut out the vertical pieces. While I was at it I also cut out the 2” box crosspieces.

I set the legs on end, lined up the base plates, pulled out my trusty Hobart Handler MIG and ran some beads in the space that I left for them:

Next I set the pieces for the front and back down on the flattest clear part of the floor, measured the difference between the bottoms of the legs and the bottom rail to get the spacing right for the caster mounts and then once I got the diagonals to match I zapped them together. To do the second side I set all the parts on top of the welded first side and used it as a pattern. Once I got it tacked I flipped it over to check how square they were:

They lined up dead on (yea, they look a little off in the picture, I tripped over the setup getting the camera).

Next I flipped them onto their tops and assembled the whole deal upside down. I set the ends on some straight 1” box to get them off the floor so any uneven spots in the concrete didn’t lift a piece off in the middle of it’s span, then clamped, bungeed, tacked (and used a few select words)… pretty much did anything necessary to hold things lined up till I got everything tacked:

You might notice that in this picture and the one before it some of the joints are tacked, some have multiple tacks, some have a partial bead and some have a full bead down one side of the joint. This is more than just a random “this is where I stopped and shot the picture” thing.

For those of you that don’t know, when you heat metal and let it cool, the spot that you heated shrinks. When you run a weld bead, the area that you weld shrinks and pulls itself tighter. I was wondering how to keep something like this perfectly square while you’re welding it and I decided I was going to use the shrinkage to my advantage. As I added each tack I measured diagonals and would add more weld where I needed things to pull tight. The thing is that as you get more pieces tacked together the whole structure gets stiffer so it takes more tacks or a bigger bead to get the same motion as you go.

FWIW, it seems like it worked well, every dimension I checked was within 1/16” or less of dead on once I got all the beads run. I was quite happy with that for this size structure and not having a dead flat surface to work on.

Here is the basic structure welded and turned upright. The only tube joints that weren’t fully welded were the top joints. This was done on purpose because I wanted a flat surface to attach the top to. I didn’t want the top resting on just a few high spots where the welds are.

This shot was the idiot check: before going any further making sure that the chip tray looks like it lines up about where I want it to. Notice that the base is _slightly_ smaller than the width of the chip tray, that is because the top will end up with 3/4” banding around it and will overhang about that much:

This is where I decided to deviate from the original plan.

Well, not exactly.

I had this thought from the very beginning but this was the point where I decided that it was necessary, and I could finally see clearly how things were lining up, so I didn’t put it in the drawings and even if I did try to I wasn’t sure what the right answer was till this point.

The debate was if a top made of 2 thicknesses of 3/4” sheet goods (plywood, mdf or particle board…) would bend under the weight of the lathe and if it would be a sturdy enough surface to attach it to.

What I decided was that I needed supports that would line up under the lathe’s feet, so while I had the chip tray centered up on the stand I marked the centerline of the lathe bolt down points on the crosspieces so I knew where I needed to add support.

I wanted something that would give me access to the back side (box tube crushes when you try to tighten a bolt through it so I only wanted a single layer), would be stiff enough and thick enough to tap. I ended up going through my pile of steel and decided on some 2x2” angle that I thought was supposed to be 1/4” thick when I bought it but it ended up very close to 3/8” thick. I cut to pieces to size, cleaned them up, tacked them in place and then flipped the whole thing over to weld it from underneath (again, no high spots to get in the way of the top laying as flat as possible).

Time to get started on the caster mounts:

The caster mounts were just some simple pieces of angle. Since I intended to use swivel casters on the tailstock end and non swivel ones on the headstock end and they required different size mounts, I made one set of mounts out of 1” angle, and the swivel end ones out of 1-1/2” angle since they had a wider bolt pattern.

In the picture above you can see that I clamped them and then used the fine adjustment tool sitting on the end to tap them into position, then I set the casters on there to make sure everything clears and lines up like expected. Finally below you can see where I welded it all together:

WOOOHOOO… this thing is starting to look like something. An upside down something, but like something…

Here the caster pads are drilled and tapped and I spent some time cleaning up the surface rust using a combination of wire wheels on an angle grinder, some 3M scotch bright and a phosphoric acid based metal prep called “Right Stuff De-Ruster Metal Conditioner and Rust Preventer”:

Comment on the Right Stuff.

I’ve used it before a few times, and have been generally happy with it, but have to an extent ignored the directions before now. It recommends brushing it on, leaving it and then painting over it, not fussing with it before painting. Specifically recommending that the sticky surface that it leaves will actually help protect the steel and help the paint adhere.

Previously, I’ve basically stopped and sanded before, after, during… any time I had a rough spot. If it looked like anything besides smooth steel it got sanded, sort of the sand and wipe down every step of the way approach and usually wipe down with something like a paint prep grease/wax/oil remover if there was any chance that I got some on it or got a hand print on it. The Right Stuff has taken care of any surface/flash rust and I never had any issues with sanding afterwards.

So this time I followed the directions. After the initial clean up I put it on (used a combination of a chip brush and a but of scotch brite dipped in it) and after it dried I painted right over the surface it left.

Well, that was a mistake. It dried with a bunch of brush marks and runs and the first coat of paint looked AWFUL. Like as in it looked like I let a blind monkey paint it by splashing it on with a mop and a bucket. I kept hoping all sorts of things were going to happen, none of them did. After letting it sit over night, giving it a good hard look and deciding that I’m not going to be able to stand leaving it that way no matter how many coats of paint I put on it I ended up sanding down most of it till it was smooth.

I put it up on stands for painting and put the first coat on with it upside down to make sure all the bottom surfaces were well coated, and the second with it right side up. For anyone wondering, that is grey Rust-Oleum Hammered:

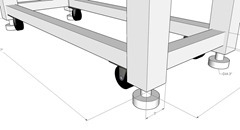

Yep, the hockey puck feet are installed, and wrapped in plastic bags so that the thing can be supported by something that does not get painted.

Here you can see one of the casters bolted in. Before anyone says it, I know that that flange is probably a bit thin to hold those threads, but I didn’t seem to be having any problems with them and figured if I did it would be easy enough to add a nut on the back side.

Oh, and the Grade 8, cadmium plated, washer head hardware is totally excessive (and I had to drill the mounting holes on the casters oversize to fit the bolts), but I have something on the order of 30# or more of these 3/8” bolts left over from a tape robot/server room decommissioning that I was involved with making those cheaper than standard 5/16” bolts and washers

So, what do you think?

One last thing to do and the stand’s structure is done. Drilling and tapping the top cross members for the lathe hold down bolts:

Another idiot check to make sure that everything lines up:

Next installment – The Top.

Stay tuned, subscribe, tell your friends, pop some popcorn or grab a beer and hang out a while.